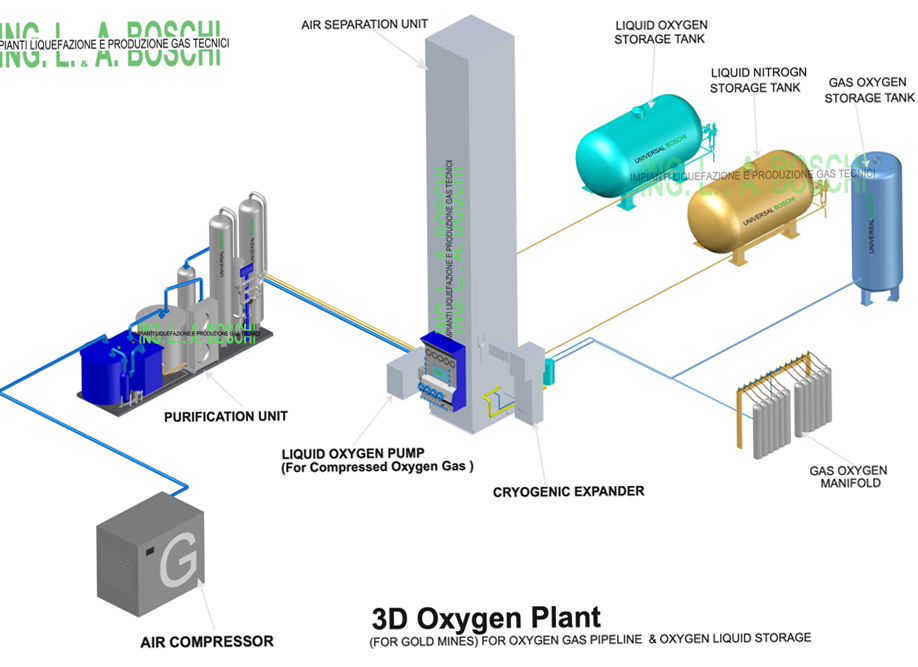

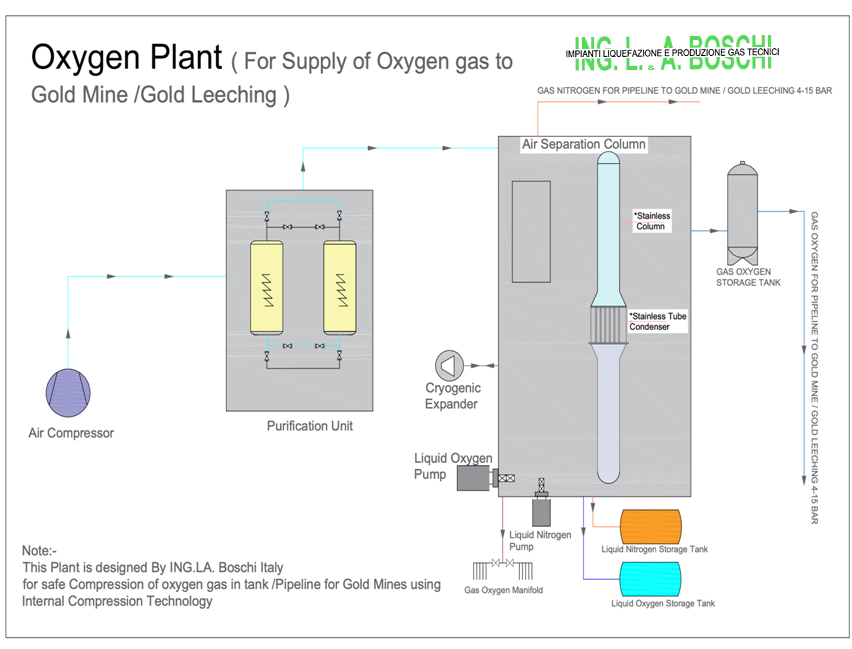

(for illustration purpose only, exact as per scope of supply)

Kindly note that our company specialises in high purity cryogenic Oxygen plants for Mining activities, since 1985, manufactures and proposes a wide rage of Oxygen plants, based on the Cryogenic technology to produce high purity Oxygen in liquid and gas form both.

We have launched the latest technology UBP-SERIES cryogenic Oxygen plant for the application of supplying high purity Oxygen 99.7% in pipeline to mines for gold and silver leaching processes.

The main advantage of the UBP Series is that the liquid oxygen in the column/coldbox gets automatically converted into pressurized oxygen gas. This allows for direct pipeline supply to the mine at the required pressure. Since the pressure requirement in most gold leaching plants is between 4 to 15 Bar, you can easily achieve this at the outlet of the plant without the need for an external oxygen compressor.

The Liquid Oxygen in the column/coldbox gets automatically converted into pressurized oxygen gas for Direct pipeline supply from the Oxygen plant to the Gold leaching plant at the required pressure .

| Capacity Table | |||||||||||

| MODEL NO. | OXYGEN GAS CAPACITY IN M3/HR | CAPACITY IN TONS PER DAY | OXYGEN PURITY | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| UBP 170 | 170 M3/Hour | 5 TPD | 99.6% | ||||||||

| UBP 300 | 300 M3/Hour | 10 TPD | 99.6% | ||||||||

| UBP 600 | 600 M3/Hour | 20 TPD | 99.6% | ||||||||

| UBP 1200 | 1200 M3/Hour | 40 TPD | 99.6% | ||||||||

| UBP 1800 | 1800 M3/Hour | 60 TPD | 99.6% | ||||||||

Note – Higher capacities also available on request upto 200 Tons per day .

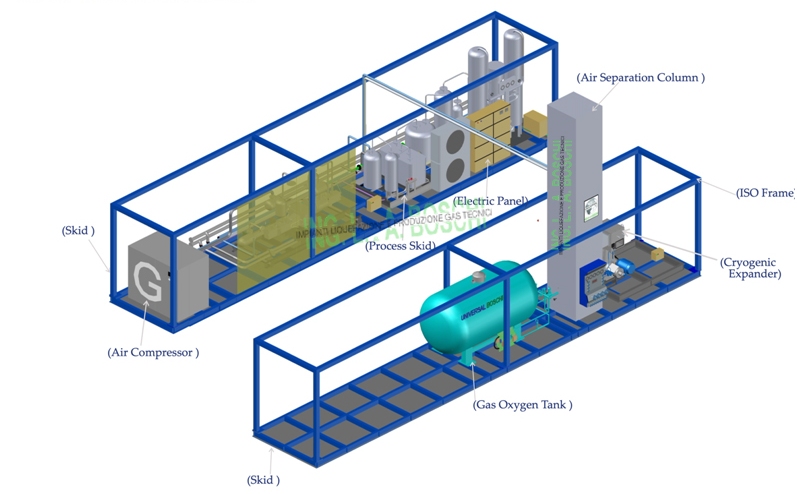

Note - 3D VIEW PICTORIAL of UBPM series for mines (Plug & play operation)

Using high-purity oxygen (99.6%) in gold leaching offers significant operational and financial benefits by accelerating the chemical reaction between gold and cyanide. Using 99.6% purity maximizes the partial pressure of oxygen, which is the primary driver for gold dissolution

| Feature | Compressed Air | High-Purity Oxygen (99%+) |

|---|---|---|

| Dissolved Oxygen (DO) | 8 mg/L (max) | 20–40+ mg/L |

| Leach Time | Standard (24–48h) | Up to 50% faster |

| Cyanide Usage | High | 40% % Reduction |

| Recovery Rate | Baseline | +5% to +10% improvement |

1. Accelerated Leaching Kinetics